LNG Conversions Next in Long Term Climate Strategy

LNG Conversions Next in Long Term Climate Strategy

2022 Q3

Matson was among the first containership operators to adopt the use of exhaust emission cleaning systems, or “scrubbers,” when it installed the equipment on its Alaska, Hawaii, and China fleets beginning in 2015. Early next year, we will be among the first to undertake the conversion of a large containership from conventional diesel power to cleaner burning liquefied natural gas (LNG) when retrofitting work begins on the Daniel K. Inouye (DKI).

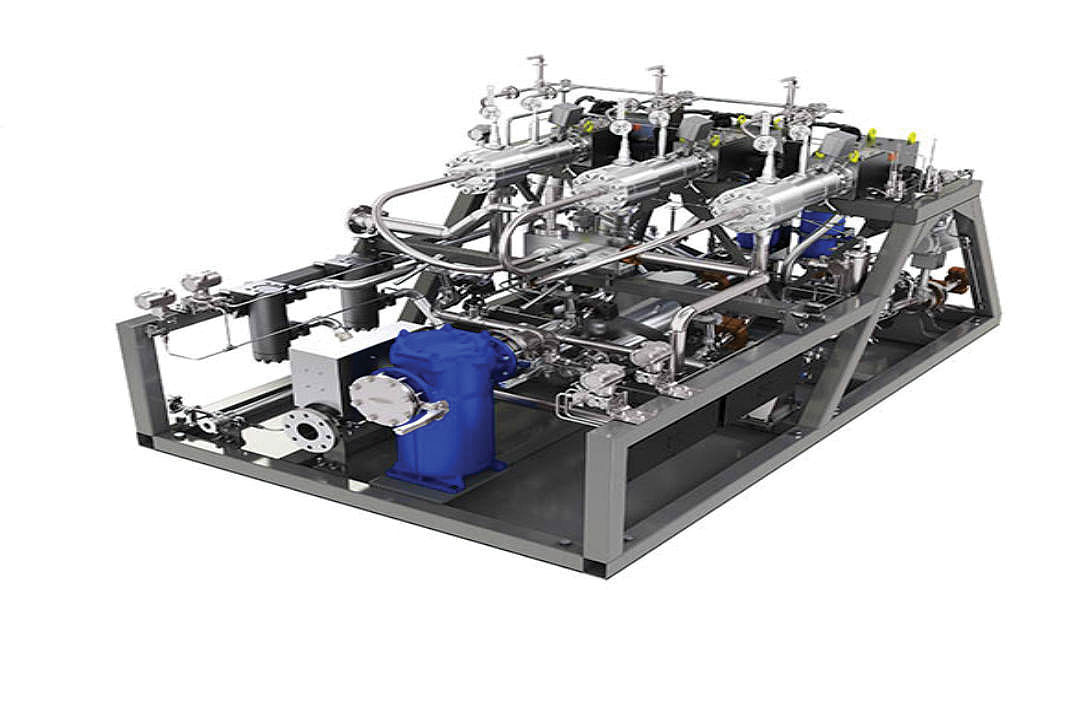

Scheduled to begin in the first quarter of 2023, the work to install special LNG fuel tanks and associated piping and other conversion equipment is expected to take five months to complete.

The conversion is expected to reduce DKI's CO2 emissions by 24%.

Built in 2018, when commercial supplies of LNG were not yet available in our network, DKI, its sister ship Kaimana Hila (2019)–and sister ships Lurline (2019) and Matsonia (2020)–were all outfitted with LNG capable duel-fuel engines in anticipation of their eventual conversion.

Following the DKI conversion, Matson plans to replace the main engine on Manukai with a dual-fuel engine. This project will take one year to complete.

“As a company that cares deeply about the environment, Matson is committed to reducing its carbon footprint through numerous short and long-term goals, including a 40% reduction in CO2 emissions by 2030 and net-zero CO2 emissions by 2050,” said Matt Cox, chairman and chief executive officer. “Conversion to LNG is a big step toward achieving these goals.”

Matson has taken numerous other steps to reduce its carbon footprint.

Last year, we retired the last of our long-serving steamships, utilizing an environmentally responsible, safe recycling facility. We’ve installed scrubbers on nine active vessels. We’ve also invested in the infrastructure necessary to use cleaner, shoreside electrical power (a process called “cold ironing,” of which Matson was an early adopter) in ports where it is available, rather than running diesel-powered generators to provide onboard power while docked.

Matson is also taking other measures to reduce fuel use and emissions, including applying high-performance, environmentally friendly anti-fouling/ friction-reducing coatings to vessel hulls to reduce drag, upgrading our vessel weather routing services to improve performance, and implementing more ecologically sensitive container design practices and refrigerants.